Done and Dusted

You know the situation, you are at a function, or a training course and the usual pre-event milling about and introducing yourself to others is going on. At some point after swapping names, you end up talking about where you live and what you do for work.

Two weeks back, I was on a training course for riding motorcycles off-road, we were standing about doing the spacially-distant/socially-awkward thing, and a guy named Lee (a professional firefighter) asks me what I do for a living, and I told him. I design battery packs for a living. He looked at me a little dumbfounded.

“surely, battery design is done and dusted.”

Done and dusted? What have I been doing with my weeks?

Winding the clock back a week in my head. A customer emails explaining that the ER14505H cell they are using for a new piece of equipment is not lasting as long as they expected. Using the average current draw of the device, it should be lasting almost 1.5 years. The cell wasn’t even getting to a year before it was no longer powering the device.

The device is like many IoT devices; it logs data and transmits that data at a predetermined interval. Most of this device’s life it has a current draw in the microamps, every 15 minutes it would wake up and take some readings. Setting up the sensor and taking readings would draw 3-6mA for several seconds.

Once an hour, the data would be transmitted. This involves a communication preamble and transmission pattern that has an average of 22mA drawn from the ER14505H cell.

Quick calculations using the average currents resulted in an estimated 472 days of operation, confirming how many days the customer thought the cell would last.

The customer had also shown that there were current spikes during the data transmission of 150mA. The ER14505H is a bobbin cell, made for a long life with a tradeoff that it can only supply small pulses of current for a very short duration. The ER14505H has a maximum of 150mA for 0.1 seconds every 2 minutes as its maximum pulse capability.

When loaded with 150mA, the ER14505H has a voltage drop of several hundred millivolts. These voltage drops can be a big problem during transmission of data; the battery voltage can drop below the devices lowest operating voltage, resulting in a loss of transmission or complete shutdown of the device.

Simple calculations don’t work so well when waveforms get a bit more complicated. Doing real-world tests to work out the life of a cell can be time-intensive; a quick answer to “how long will this battery last” isn’t possible. Enter simulation software.

What is simulation software…

Simulation software uses mathematical and table-based data on the items under test to speed up processing, processes that in real life can take years to eventuate can be analysed in a short time. We can see how cell heating across a high power battery pack affects life and run time, simulate what happens if a cell fails, developing code for battery management systems and testing these over many possible failure scenarios before committing to hardware and software, averting what could be dangerous and lengthy tests. Solar yield and consumption for varying operational duty cycles can be simulated as well. If it can be reduced to a mathematical model, you can simulate it.

Using the information gleaned from datasheets and supplementing that with real-world cell tests, a quick software model of the ER14505H with enough information to get a general idea of what was going on was created. The current waveform for every cycle of sensor and transmission was also created.

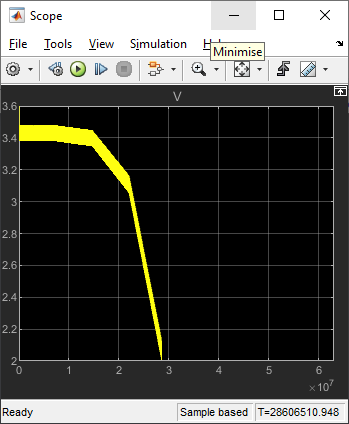

First, we ran a simulation without the 150mA spikes, the result was 517 days of operation down to 2V. In Figure 1. We see a scope view of the discharge curve of the cell. As we put together the model quickly, the curve is more a series of straight lines.

Figure 1. Discharge curve without 150mA pulse

Then we ran the same test but this time with the 150mA spikes. In Figure 1 you can see how the spikes affect the voltage, the bottom of the yellow band shows the voltage the cell would drop to. The result is that the 2V minimum has been reached at 281 days with an unusable 17% left in the battery.

281 days is closer to what the customer is seeing on-site and is less than what was promised to the end-user. That can be an embarrassing and costly mistake.

A larger battery would solve the run time issue, but since the product and enclosure have already been designed, it would be difficult to replace the battery with a larger one.

Figure 2. Discharge curve with 150mA pulses

Introduce the supercapacitor SCL1016. What is it? How does it work?

One way to fix voltage ripple in an electronic circuit is to add a capacitor, adding a capacitor to overcome the voltage dip of the bobbin cell may be a solution here as well. The problem with a standard capacitor is that self-discharge can be quite high. We would reduce the voltage drop during the 150mA discharge pulses, but we would add a discharge level that would negate any positive effect from the capacitor. A supercapacitor with its higher capacitance has a similar problem with high discharge.

Enter the Li-Ion capacitor; this device acts like a capacitor and a battery, a hybrid. It has a low self-discharge of just 0.25µA and is rated in mAh rather than Farads.

We created a model of one of the SLC1016 from the Fanso range and added it to the simulation. Adding the SLC1016 reduced the voltage sag introduced by the 150mA communication spikes. The result? A 331 day run time and a battery that was taken down to 2.7% capacity remaining. The results are shown in Figure 3.

Figure 3. Adding an SLC1016 has increased user time to 331 days.

Can the run time be improved upon with a larger value hybrid supercapacitor? Can a spiral wound cell with a better pulse capability but its compromised lower capacity cell work better? If the communication operation of the device is redeveloped, or the ambient temperature changes due to environmental factors, what will the effect on battery life be?

With alterations to parameters in the simulation, we can quickly find out. The simulations can be done much faster than real-world tests, by replacing the SLC1016 model with an SLC1025 model, we had an answer (Figure 4) in the time it takes to make a coffee. And the results can be drilled down to view the voltage discharge curve from a discharge pulse lasting no longer than 1mS as can be seen in Figure 5.

Figure 4. Adding an SLC1025 has further increased the device operation time to 533 days.

Figure 5. a small portion of the data from a simulated 533-day test.png

Done and dusted? How do I explain a snippet of my week in a very short time and keep anyone listening interested?

I think people forget that a battery is a critical part of a powered device, its early failure in mission-critical hardware can be life-threatening, I’m sure a firefighter would understand that.

With the limited time and with the limited interest of those around me I just summed my job as “we do battery packs for the strangest things, like logging equipment that measures the temperature/noise/vibration of equipment or the temperature of a cow’s entire intestinal tract during digestion.”