Battery in a tube

Brief. Design a battery for an e-bike. The battery will be in the downtube and therefore have a diameter restricted by the tube dimensions. The customer requested 10S to match a chosen motor and controller.

2P-10S, 20 cells in a tube 42mm ID. 550mm long. Some of the 550mm are taken up by angled tube ends and will also need to fit a BMS.

Figure 1. 2P-10S arrangement in a tube.

Building the pack will require 7 pairs of 2P to make up two columns and then a column laid out Portuguese chicken style of remaining 3 pairs of cells. This arrangement results in about 470mm long battery.

In this arrangement, there will be 3 pairs with one cell having a short connection to the next series cell while the other has a long connection resulting in unbalanced negative connections. You can see this in the figure 1 arrangement, one negative tag is the full length of the two cells (130mm) whereas the other has a short link to the next cell.

The tag resistances in the diagram show the inbalance using 6mm x 0.2mm nickel tags to connect cells.

The schematic layout was put into Matlab for simulation. The extra resistance was placed in three of the negative legs as per the way the battery will be laid out.

Figure 2. A small section on the Simulink Matlab diagram.

I collected data on my own e-bike to use in the simulation, as below. The bike was heavily loaded with gear and food.

Figure 3. Collected e-bike power data.

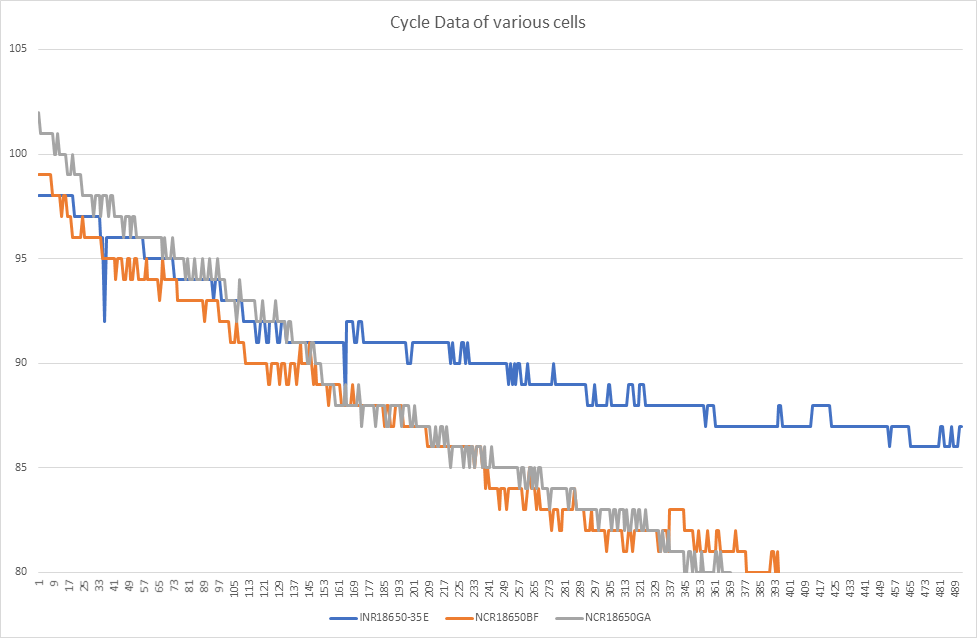

I used the power data from the bike ride to create a simulation load on the battery. Cell model data is using the NCR18650GA collected during recent testing.

In Figure 4 below you can see the effect of the longer tab length on one cell over the other.

The graph below shows the difference in current between the two cells. The cell represented by the blue line gets a higher portion of the load. This cell will age more quickly than in a well-balanced pair.

The layout of the tags can affect the life of a battery pack if some cells deliver a higher portion of the power when it is requested.